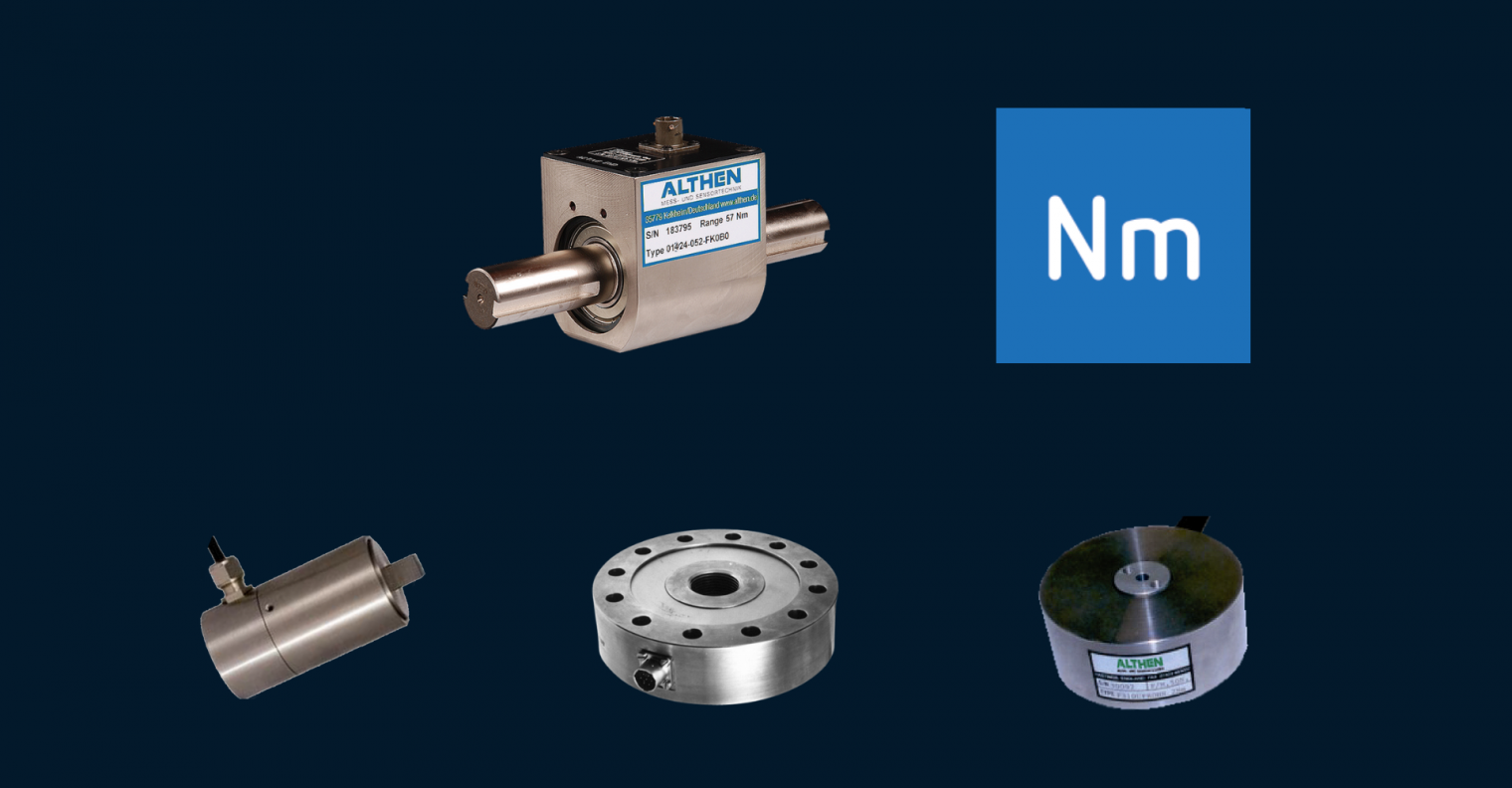

Torque sensors

Torque sensors have a wide range of industrial applications. One of their main tasks is to determine the efficiency of the engine, i.e. actually accelerated engine power in relation to energy consumption. Such measurement systems play an especially important role in ship engines. Permanent automated monitoring of the efficiency of the ship’s engine and the taking of timely preventive measures allows to achieve enormous fuel savings during ship’s engine operation.A torque sensor or torque transducer is a device for measuring and recording the torque on a rotating system, such as an engine, crankshaft, gearbox, transmission, rotor, a bicycle crank or cap torque tester.

The torque sensor (or torsion meter) is mounted directly on the loaded element (ship shaft) and determines the amount of shaft twisting between two marks. Depending on the method of reading data, torque sensors can have a different design: contact and contactless, pulsed, inductive and photoelectric. The higher the speed and accuracy of the measurement is calculated device, the more complex the design it has. The selection is made in accordance with the characteristics of the vessel and its operational features. If you do not know how to choose a rotary torque sensor, what performance characteristics it should be designed for, then contact us by phone, we will advise you, and also we will help with ordering.